GE Arctica Refrigerator Help

Some repair info and tips for the GE electronic refrigerators....

- Frozen water line for the chilled water dispenser

- Some defrost problem helps and tips

- Some freezing in the fresh food section trouble makers

- Some noisy evaporator fan motor helps

- Some temperature and defrost thermistor helps and tips

If the heater ohms good and the thermisiter is within specs you need the tech sheet or manual to see that, then its board time. The overlimit thermostat is not a simple bimetal either, it is there in case of welded contacts on the board only. It should be closed almost always.

WHY Force the Arctica to Defrost if it Don't Want to? Don't bother using the self-diagnostics feature to force a defrost cycle. On some models – those with control knobs - which technically are not Arctica models (Arctica models have plastic liners with touch pads – Standard GE electronic models with metal liners have knobs) servicers would have to invest in parts to build a "test" control panel, complete with touch pads and digital displays, to achieve this (self-diagnostics) function. Instead, save both time and money by following this helpful Arctica Tip: If a frosted evaporator or a "frost block" is apparent, initiating a defrost cycle may not reveal anything helpful anyway. First, disconnect power and then simply check the resistance across the defrost heater and bimetal circuit at the main board located at the backside. The two associated wires at the main board are almost always BLUE and ORANGE. The heater/bimetal circuit should normally read around 30 ohms roughly. Next, check the evaporator thermister at the main board between thermister input terminals J1-4 (Blue/White) and J1-5 (Blue) to determine that its resistance is greater than 1.2k ohms but not more than 166.8k ohms depending on its ambient temperature. If thermister resistance falls within this range according to temperature (Approximately: 6k ohms at 70ºF – 16.3k ohms at 32ºF – 51k ohms at 0ºF) and the heater/bimetal circuit is diagnosed as good, then replace the main board. Note: Always check the tech sheet per specific model to verify wire colors and terminal locations.

The best way to determine what has caused a non defrosting GE electronic control model is to first access the control board. Jump terminals line power to defrost, (J4 and J9). An amp probe should be placed on this jumper wire to determine current draw of the defrost circuit. A three amp draw is what is normal for this circuit. This will eliminate checking behind the evaporator cover to determine a defective heater or over temp device (defrost terminator). Note: This test is only to check the defrost circuit. It does not initiate a defrost cycle. If the unit is in any other cycle than defrost, that cycle will continue to operate as well.

GE refrigerator M # PTS25LHSARWW this refrigerator is making a howling noise coming from the freezer . What can be done to keep this noise down a little.

Sometimes the fan motor itself ( especially if ice is building up around the blade )... But...more often than not the electronic control board is trying to run both speeds of the fan motor at the same time = new board time.

Main Mother board

OR...

This repair will address fan/motor noise such as humming, loud whirling, blade hitting ice and rattling or roaring sounds.

Side-by-Side models with metal liners:

- Follow procedure for reducing freezer compartment moisture involving installing the latest version of the main control board, and a new evaporator cover.

- Install new Freezer fan assembly 25' use WR60X10100 20'/22' use WR60X10101

Side-by-Side models with plastic liners:

- Install new freezer fan assembly WR60X10102 .

While at a customers performing some other services and him being aware of my service tech background I found myself after some investigation, looking at a water line frozen inside the freezer door. I was able to get it defrosted by the skillful although wet application of some warm water introduced into the line. For a couple of weeks it worked anyway...so I'm online doing a search about it and I find a few posts about it. Several recommend a heater kit , part number WR49X10173, GE SXS model # GSS25IFPCWW

Some pictures and reference material from that repair....thankx fyxxez!

- Instructions 1 (this come with the part)

- Instructions 2 (this comes with the part)

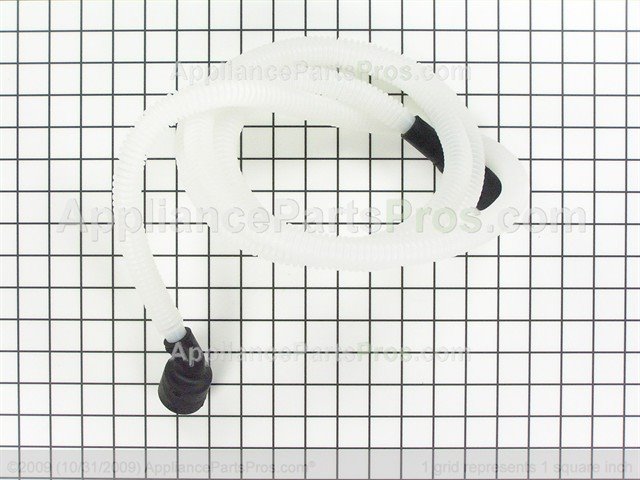

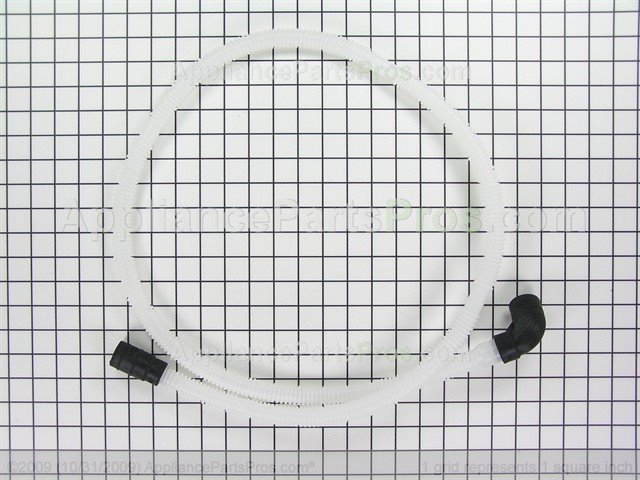

- Picture 1

- Picture 2

- Picture 3

- Picture 4

- Picture 5

There have been intermittent cooling or poor performance issues on PFS/PDS BTM units. The condenser fan motors were found not running up to speed - causing large fluctuations in temperature. Check the fan speed voltage at the main board j2 connector between the pink and white wires, the voltage should be 11-12vdc. The test should be preformed with the fan motor in the circuit, if you see the voltage dropping below 10vdc replace the condenser fan motor and the main board.

GE model PDS22MBSBBB, the condenser fan motor was not running. Customer had a new motor but that would not work either. I am getting dc voltage to the motor and I did a continuity check on the wires from the board to the motor, all is good. Both motors ohm out at about 1500 ohms. Unit is only 2 years old and I don't think both motors are faulty so I leaning towards the board. - Repair: A new mother board corrected this problem.

Condenser fan motor

Main control board

General Electric Refrigerator Parts

Related Links

- GE/Hotpoint Temperature Sensor

- GE/Hotpoint Refrigerator Defrost Heater and Bracket Assembly

- GE/Hotpoint Defrost Thermostat